Research - African Journal of Food Science and Technology ( 2022) Volume 13, Issue 5

Received: 22-Mar-2022, Manuscript No. AJFST-22-58119; Editor assigned: 24-Mar-2022, Pre QC No. AJFST-22-58119; Reviewed: 07-Apr-2022, QC No. AJFST-22-58119; Revised: 12-May-2022, Manuscript No. AJFST-22-58119; Published: 18-May-2022, DOI: http:/dx.doi.org/10.14303//ajfst.2022.021

The paper entails the design and fabrication of manually operated Okazi (Gnetum africanum) leaf slicing machine. Slicing of Okazi leaf is one of the most significant and yet energy demanding post-harvest operations in Okazi leaf processing. Unlike other leafy vegetables, Okazi has a thick paper- like leaf which is usually very difficult to cut due its fibrous nature. The developed machine consists of four mechanisms i.e., the crank with length of 80 mm, the follower, sliding lever with 140 mm and the cutting blade which was tested with 60% slicing efficiency and was confirmed working. The machine was designed to enhance the hygienic slicing of Okazi leaf materials to prevent knife related injuries for both commercial and domestic use. The constructed machine was evaluated through physicochemical studies using 50% hand slices of Okazi and 50% machine slices of Okazi leaf from different locations. The moisture, ash, fat, crude fibre and carbohydrate contents ranged from 13.0-13.05, 19.00-18.96, 5.38-5.35, 6.68-6.77, 7.39-7.37 and 48.59-48.64 respectively. There were no significant (p>0.05) differences between the hand and machine slices of Okazi leaf which indicates that slice thickness has no implication on the nutritional status of the vegetable.

Hand and Machine Slices of OKAZI leaf, Slicer and Knives, Okazi

Okazi (Gnetum africanum) is a leafy vegetable that belongs to the family Gnetaceae and occurs naturally in humid forest zone from Nigeria to Central African Republic and to Angola It is an ever green dioecious forest perennial liana that grows up to 10 m long but sometimes longer and branchedGnetum africanumleaves are widely consumed in the South Eastern Nigeria due to its palatability and taste and often cooked with water leaves (Talinium triangulare) to produce edikang that gives the soup a special flavour. The plant grows as a wild evergreen climbing plant in the rain forest of Nigeria where it is searched for and highly priced in the regional markets. This wild variety is termed wild species while the recently domestically cultivated ones in the South Eastern Nigerian homes as exotic plants are termed the domestic species. Gnetum africanumOkazi is traditionally a wild vegetable. According to perennial vine that grows approximately 10 metres long with thick paperylike leaves growing in groups of three. The leaves may grow approximately 8 cm long, and at maturity, they will produce small core-like reproductive structures (Akindahusi & Salawu, 2005).

Okazi (Gnetum Aficanum) has a characteristic thick paperylike leaf which is usually hard to cut due to its fibrous nature. Due to the antioxidant, anti-inflammatory and anti-carcinogenic properties of Okazi, the leaf can be used as remedy for certain ailments and diseases. Okazi leaf is an excellent source of dietary fibre, protein, vitamins such as vitamin A and C, minerals such as sodium, magnesium, calcium, iron, zinc, manganese, potassium, copper, and essential amino acids that are required by the body. The relatively high content of protein in Gnetun africanum suggests why this plant contains a high amount of essential acids that can act as an alternative energy source especially when the carbohydrate metabolism is damaged due to glucogenesis. Vegetables go through additional preparation steps of washing, sorting, grading, cutting or slicing, and packaging in to retail size containers prior to use or for sale. Slicing machine has become important equipment in the processing of vegetables. Vegetables can be sliced traditionally or locally by hand using tools such as knife, chopping board or wooden stick and tray and this contribute to high wastages, poor quality of cuts as a result of manual hand operations, energy and time consuming, not quick nor evenly cut, reduces productivity, increases physical labour and prone to injury when not properly handled. Slicing of Okazi leaf is seen to be the most tedious and difficult aspect of processing leafy vegetable due to its papery-like and fibrous nature. The design and fabrication of a cheap and portable manually operated Okazi leaf slicer could avert the problems associated with manual slicing of Okazi leaf encourage the propagation of the plant by famers thereby reducing its scarcity (Akinyeye et al., 2011).

Selection of materials

The materials selected for the fabrication of Okazi slicer include stainless steel and mild steel.

Okazi (Gnetum africanum) leaf of 2 kg was procured from 808 Imoke Street, University of Nigeria Nsukka and 2kg procured from Uzoakoli in Abia state all in Nigeria. Okazi sample was sorted and cut into sizes (Okerulu et al., 2015). Okazi (Gnetum Africanium) leaves were detached from its stalks and parts of the fresh leaves were used for moisture determination and the other parts were sliced and air dried in room temperature. The dried sample was pulverized into fine powder using a sieve mesh of size 2.0 mm. The dried pulverized samples collected were subjected to proximate and micronutrient composition at same time (Orwa, 2009).

The product development process flow for this project is showed in Figure 1 (a,b) below:

Planning

↓

Concept development

↓

Detailed design and fabrication

↓

Testing and refinement

↓

Final design

Okazi (Gnetum africanum) Leaf Slicer Development process chart.

Mechanical properties of the leaf depend on leaf developmental stages as young leaves are much softer than old leaves.

Design Calculations

In the cutting operation, the cutting stoke is the only effective stroke, while returning back after creating a slice. The cutting tool retracts back to take the forward stroke without doing any work. According to grass of law and inversion condition (Ogunlada et al., 2011).

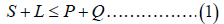

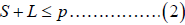

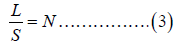

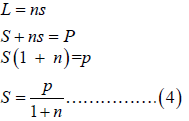

The four bar mechanisms are stated below:

Let S = length of the shortest link

L = length of the longest link

P = length of one remaining link

Q = length of other link

In the design, the last link is hinged to the lever of the scissor hence Q = 0

Ratio of the crank

The ratio of the crank to the connecting rod is given by:

Where 0 ≤ n ≤ 4

Hence L = ns

and  of the stroke length from geometric consideration

Length of stroke = 160 mm.

of the stroke length from geometric consideration

Length of stroke = 160 mm.

Base of the length of the cutting edge of blade =  × 160

mm

× 160

mm

S = 80 mm

If N = 0.75 then

P = 80 (1 + 0.75)

P = 140 mm

L = 60 mm

Therefore, crank length = 60 mm

Follower length = 60 mm

Coupler length = 140 mm

Power and Efficiency calculations

The speed of the motor N1 = 2880 rpm

No of teeth of the drive gear, D = 10

No of teeth of gear, N2 = 360

Gear equation

Gear equation

Speed of crank, D2 = 80 rpm

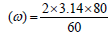

Angular speed of the crank

(ω) = 2π N

(Ɯ) = 8.378 rad/s

Velocity of the piston

Velocity of piston =ωγ {Sinθ + Sin2θ } (2θ / 2n)}

= 8.378 X 0.08 (Sin 30 X (2 x 30)] 2(0.75) = 6.87 m/s

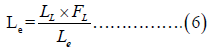

Power developed in cutting

Power developed in cutting = F × V

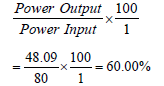

From the Lever principle,

FL = force required to slice 40 mm thickness of Okazi leaf

LL = lever arm length of load

Fe = force required to apply on the effort arm

Le = lever arm of the effort

From the scissor design,

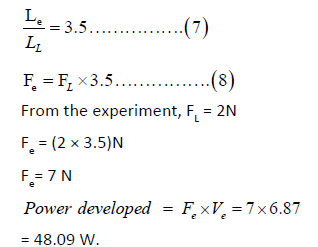

Slicing efficiency of Okazi leaf Slicer

From the motor specification, power requirement is 120 volts

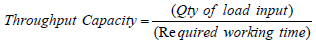

Throughput capacity (TPC) of the machine

Fabrication procedures

The fabrication work was carried out at Magnus fabrication workshop, Slaughter Road, Nsukka, Enugu state Nigeria. The manufacturing procedures adopted for the construction of Okazi slicing machine include: Design and analysis, cutting of the sheet metal, forming into desired shape, patry and facing, welding of the parts together and painting. The main drive mechanism was designed using an engineering design and stimulation software called SOLIDWORKS. After the mechanism was confirmed, the drive side of the machine was fabricated and tested. The support frame and cover (body) of the machine was constructed. The machine was painted with rust-oleum (7519838) professional high stainless-steel paint to prevent corrosion of some critical part, while the food passage was constructed with stainless steel.

Performance Evaluation of Okazi leaf Slicer

The test performance of the slicer was carried out at Magnus Fabrication Work shop, Slaughter Road, Nsukka, Enugu State Nigeria. During the performance evaluation of the machine, two experienced Okazi slicer from Abia state and Nsukka, Enugu state, handled the manual slicing of the Okazi using sharp knife, tray and chopping board. The machine was fed manually and the slicing operation was carried out in 5 runs to determine the time taken to complete the slicing operations. The machine was tested with the Okazi leaf and the throughput capacities (TPC) for five runs were determined. Both physical test and qualitative analysis of Okazi leaf slices cut with the use of knife was compared with that of the machine slices. Effect of moisture content of the vegetable on the rate of slicing was studied as well. The moisture content, protein, crude fibre, crude fat, potassium, sodium and ash were determined using the method of AOAC (2010). Carbohydrate content of the samples was determined by difference as reported.

Vitamin A content was determined using the method described by (Prentice & Langridge,1992). Vitamin C content was also determined using the method described.

Statistical analysis and experimental design: The experimental design used was completely randomized design (CRD). The data was analyzed using a one-way analysis of variance (ANOVA) and separated by Duncan’s new multiple range tests (DMRT). Significance was accepted at p < 0.05 according (Figure 2).

Component Parts of Gnetum Aficanum (Okazi) Leaf Slicer

The frame: The frame serves as a support to the motor, drive mechanism, hoppers (both feeding and discharge points) and machine cover. The length, width and height are 450 mm, 210 mm and 290 mm, respectively. The frame was constructed with 5 mm thick metal steel plate with angle iron as a stand (Figure 3).

DC motors: Electric motor act as a prime mover thereby converting electrical energy stored in the battery into mechanical energy via shaft power. The motor utilizes 12 V and its power rating is 120 W. The original speed of the motor is 2200 rpm but with the aid of the gear arrangement pre-coupled into the motor, the speed is brought to 80 rpm.

Battery: The battery is the source of energy storage making it possible to be able to run the machine with or without electricity. The battery is 12 volts, 7.5 AH rated with rechargeable characteristics.

Hopper: There are two types of hopper used in this project which are the feeding and discharge hoppers both constructed with stainless steel in other to minimize corrosion. The feeding hopper was placed at angle 60o to the horizontal while the discharge hopper was 75o to the vertical (Figure 4).

Charging circuit: The charging circuits consist of transformer, bridge diode for rectification, smoothing capacity and voltage regulator. It is responsible for recharging the energy back into the battery after discharge and switch over to utility when there is power supply. The charging circuit supply 12 V and 4 - 5 A to the battery which takes about 4 hours to fully recharge the battery back after heavy discharge.

The drive mechanism: the machine does not make use of quick return mechanism to operate. In the quick return mechanism, the cutting stroke (movement) is slow, while the return stroke is fast. With this mechanism, there is reduction in the time used for the slicing of a given quantity of Okazi leaf. Slicer crank mechanism has a version called quick return mechanism which was used to design this project. The mechanism consists of 4 links which include:

Crank: This part completes 360o rotation and is directly coupled to the prime mover in the design. The crank of length used in this project was 80 mm mild steel plate (Figure 5).

Follower: This member undergoes both translational and incomplete rotation; the main function is to transfer energy from the crank to the sliding lever. It is made up of mild steel rod with two chrome steel bearing (Figure 6).

Sliding lever: It undergoes majorly translational motion which is connected to the cutting blade while the other slides with the follower. It is made up of mild steel with length of 140 mm.

Cutting blade: This undergoes up and down motion popularly known as reciprocating. This up and down motion is what is utilized in cutting the Okazi leave into desired shape.

The cover: The drive is being protected from operator getting their hand stock into the drive. The cover is made up of mild steel painted with stainless steel paint, formed and welded into desired shape.

The base plate: This is used to cover the machine in order to prevent flies and other pest from gaining access into the machine from the bottom. The base plate is made up of stainless steel with 3 mm thickness.

The Machine (Okazi Leaf Slicer)’s Working Principle

Electric energy stored in the battery or readily available from utility is converted into mechanical energy by the use of DC motor. The mechanical energy is made available in the form of rotating shaft power. Some set of arrangement of linkages called mechanism converts this rotational power to reciprocating power, which is utilized in slicing Okazi leaves. This reciprocation motion occurs at the cutting blade in which one blade is kept stationary and the other reciprocates and slides on the fixed member. The operator manually arranges the Okazi.

Leaf and feeds it into the machine via the feeding hopper. The blades perform the cutting action, while the operator ensured that the required size is what was fed into the machine. Provision was made for recharging the battery in order to use the machine without utility supply.

The result presented in showed a relatively high moisture content especially in sample C and D (Okazi from Uzoakoli, Abia State) against higher values 31.6% for Gnetum africanum seed reported by (Ekpo, 2007) and some vegetables such as Piper guineese and Gongromea latifolum (Mensah et al., 2008), 81.36% recorded in Bressica oleraecea 83.75% in Ptercarpus soyaubixii and Gnetum africanum. The moisture content of the manually and machine sliced Okazi leaf varied significantly (p ≤ 0.05) according to the plant species harvesting area. This indicates that there were no significant (p ≥ 0.05) difference with the machine and knife sliced Okazi leaves of sample A and B, C and D. The crude protein content of machine and hand slice Okazi leaf from different locations ranged from 16.49 to 19.00% was high compared with 17.50% reported by (Ekpo, 2007) for seeds of Gnetum africanum, 19.67% and 20.80% for the leaves of Gnetum africanum and Cucurbita pepo respectively (Iheanacho & Udebuani 2009). However, it is also 1.3 times higher than those obtained in leaves of Kigelia africana, a plant used for nutritional and pharmacological purposes in West and South Africa. The protein content obtained were comparable to data obtained. Who indicated protein values of Okazi leaf between 16.6 to 18.9% in the leaves from Congo. Also obtained crude protein content of 20.12% similar to those obtained in this paper. The high protein suggests high number of essential acids which serves as an alternative source of energy when the carbohydrate metabolism is impaired via glucogenesis (Iheanacho & Udebuani, 2009) (Table 1).

| Samples | Moisture | Protein | Fat | Ash | Fiber | Carbohydrate |

|---|---|---|---|---|---|---|

| Sample A | 13.01b± 0.02 | 19.00a± 0.02 | 5.38b± 0.06 | 6.68b± 0.02 | 7.39b± 0.01 | 48.59a± 0.10 |

| Sample B | 13.02b± 0.01 | 18.96a± 0.02 | 5.35b± 0.06 | 6.77b± 0.18 | 7.37b± 0.02 | 48.64a± 0.17 |

| Sample C | 29.10a± 0.01 | 16.49b± 0.02 | 6.25a± 0.01 | 8.22a± 0.03 | 24.04a± 0.02 | 15.90b± 0.07 |

| Sample D | 29.10a± 0.01 | 16.49b± 0.02 | 6.26a± 0.01 | 8.23a± 0.03 | 24.05a± 0.02 | 15.91b± 0.07 |

Table 1. Proximate composition (%) of manually and machine sliced Gnetum africanum (Okazi leaf).

Values are mean ± standard deviation triplicate determination. Values bearing different superscript within the same column are significantly (p ≤ 0.05) different.

Key: sample A = Machine sliced Gnetum africanum (Okazi leaves) from the farm at 808 Smoke street, Sample B = knife sliced Gnetum africanum (Okazi leaves) from same farm with sample A, Sample C = machine slice Gnetum africanum from the farm at Uzoakoli, Amaukwu in Abia state. Sample D knife sliced Gnetum africanum from same farm with sample C. (Table 2).

| Samples | Vitamin A(mg/100g) | Vitamin C(mg/100g) | Potassium | Sodium |

|---|---|---|---|---|

| Samples A | 12.01b± 0.01 | 33.70b± 0.26 | 2.03b± 0.01 | 0.89b± 0.01 |

| Sample B | 11.80c± 0.01 | 33.57b± 0.01 | 2.03b± 0.02 | 0.90b± 0.01 |

| Sample C | 23.01a± 0.03 | 33.57b± 0.02 | 2.07a± 0.02 | 1.04a± 0.01 |

| Sample D | 23.00a± 0.02 | 37.01a± 0.02 | 2.08a± 0.01 | 1.05a± 0.01 |

Table 2. Shows the micronutrient composition of machine and manually sliced Gnetum Africanium leaves (Okazi) from different locations.

Values are mean ± standard deviation triplicate determination. Values bearing different superscript within the same column are significantly (p ≤ 0.05) different.

Key: sample A = Machine sliced Gnetum africanum (Okazi leaves) from the farm at 808 Smoke street, Sample B = knife sliced Gnetum africanum (Okazi leaves) from same farm with sample A, Sample C = machine slice Gnetum africanum from the farm at Uzoakoli, Amaukwu in Abia state. Sample D knife sliced Gnetum africanum from same farm with sample C.

The crude fat content of Gnetum africanum (Okazi leaf) from different locations ranged from 5.35% in sample B to 6.26% in sample D. The crude fat content of the slices of Okazi leaf in sample A and B were not significantly (p ≥ 0.05) different, but significantly (p ≤ 0.05) different from samples C and D, which was due to the area of harvesting environmental factors. The crude fat obtained was higher than the value 2.79% obtained. Ekpo (2007) recorded a value of 3.15% of Gnetum africanum seed. The machine slicing of Okazi leaf from different locations did not have effect on the crude fat content.

The ash content of Gnetum africanum (Okazi leaf) ranged from 6.68 to 8.23%. The result obtained was in line with 6.70% reported by less than 1.2% obtained by (Ekpo, 2007) for seeds of Gnetum africanum, 4.32% for Riglabra and 4.03% for Ampelocissus Africana but lower than some vegetables such as 20.6% for Pterocarpus mildbraedii and 20.05% for Talinum triangulare.

Furthermore, the ash content obtained is less than the value 9.05% for bitter leaf, 13.01% for scent leaf and 8.54% for Ugwu leaf.

The crude fibre content of Gnetum africanum (Okazi leaf) ranged from 7.37% in sample B to 24.05% in sample C. The value obtained in this project was higher than the value 7.16% reported by lower than 0.80% recorded for the seeds of Gnetum africanum. The high crude fibre content may contribute to a reduction in the incidence of certain diseases like colon cancer, coronary heart disease, diabetes, high blood pressure, obesity and other digestive disorders. There were no significant (p ≥ 0.05) differences between the sample from different locations.

The carbohydrate content of Gnetum africanum ranged 15.90% in sample C to 48.64% in sample B. the high carbohydrate content is said to be high for a vegetable material but the value was justified by the 87.62% for Gnetum africanum seed 52.32% reported for Pachira glabra and 45.92% for Ampelocissus africana seed flowers 52.18% for Amaranthus hybridus (Akubugwo et al., 2007). The high values obtained in sample A and B, was due to low content of fibre and moisture whereas the high value was probably due to high content crude fibre and moisture. Therefore, there were no significant (p ≥ 0.05) differences in the slices of Gnetum africanum from different locations (Table 3).

| Runs | Machine Sliced | Hand Sliced | ||||

|---|---|---|---|---|---|---|

| Capacity, g/min | Slice thickness, cm | Slice length, Cm |

Capacity, g/min | Slice thickness, cm | Slice length, cm | |

| 1 | 4 g/min | 0.5 | 3.9 | 5 g/min | 0.2 | 3.0 |

| 2 | 4 g/min | 0.4 | 3.7 | 3.75 g/min | 0.1 | 3.1 |

| 3 | 0.6 | 3.7 | 7.5 g/min | 0.1 | 3.2 | |

| 4 | 5 g/min | 0.5 | 3.8 | 5 g/min | 0.1 | 3.1 |

| 5 | 7 g/min | 0.4 | 3.6 | 6 g/min | 0.1 | 3.0 |

Table 3. Performance Evaluation of the time taken to slice Gnetum africanum leaves (Okazi) using the machine and sharp knife.

Key: sample A = Machine sliced Gnetum africanum (Okazi leaves) from the farm at 808 Imoke street, Sample B = knife sliced Gnetum africanum (Okazi leaves) from same farm with sample A, Sample C = machine slice Gnetum africanum from the farm at Uzoakoli, Amaukwu in Abia state. Sample D knife sliced Gnetum africanum from same farm with sample C.

Gnetum africanum (Okazi) leaf ranged from 11.80 mg/100 g in sample B to 23.01 mg/100 g in sample C. The vitamin C content of the samples was high and ranged from 33.01 to 33.70 mg/100 g.The value obtained is lower than 56.87 mg/100 g for Gnetum africanum reported by there were no significant (p ≥ 0.05) differences in the machine and hand slices of the leaf from different locations.

The vitamin A content of Okazi leaf slices from different locations ranged from 23.00 to 23.01 mg/100 g. The value obtained can be compared with 25.22 mg/100 ml for Ficus capensis, 94.45 mg/100 ml for Solanum melongena, 108.48 mg/100 ml for Moringa oleifera lam reported by Vitamin A is important for normal vision, gene expression, growth and immune function by bits maintenance of epithelial cell functions Slicing the vegetable using the fabricated machine had no effect on the vitamin contents. The potassium and sodium content ranged from 2.03 to 12.08 mg/100 g and 0.89 to 1.05 mg/100 g respectively. As the main intracellular action in mammals, potassium and sodium are involved in maintaining cell volume, enzymes activity transmission of nerve impulses, and regulation of blood pH (Pasch, 2006). Including Gnetum africanum leaf in a diet could therefore contribute to maintain and promote those physiological activities. Therefore, the machine does not have effect on the micronutrient composition of Gnetum africanum leaf.

From, the capacity (g/min) for the five runs ranged from 4 to 9 g/min in machine sliced and 3.75 to 7.5 g/min in hand sliced Okazi leaf. It was observed that machine slicing of Okazi leaf yielded more tones per minute compared with the hand sliced Okazi leaf. The time taken to slice the leaf using the mechanized machine was more compared with the hand slicing and the slice thickness and length differed. The variation in slice thickness and length which was more in machine Okazi slicer and this is because, in the mechanized machine, the feeding could not be adequately controlled as it was fed manually. The slice thickness obtained from the result above was more than the value 3.05 mm for hand slice and 1.86 mm for motorized okra slicer and the time taken to slice Okazi with both hand and machine was more than the time 90 minutes recorded. The slice length of Okazi leaf was more than the value 0.251 m of sliced aloe Vera recorded. During the slicing process, they were no moisture losses from the machine and hand slice regime (Ekpo, 2007).

Design, fabrication and performance evaluation of Gnetum africanum slicer were carried out to alleviate the fatigue in manual slicing of Okazi leaf. The slicing machine was constructed in such a way that it is portable, conserves energy, easy to use, light weight and efficient. Based on the performance evaluation, the equipment performed well in slicing of Okazi leaves. The efficiency in terms of rate of slicing was highest in machine sliced compared to the hand slices and the time required to slice a given quantity of Gnetum africanum leaf using the machine was considerably decreased. The variation in the thickness of Okazi sliced manually and with the use of machine does not have any implication on the nutritional status of the leaf. Also, the proximate and micronutrient composition of Gnetum africanum (Okazi) leaves from different locations obtained in his work showed no significant (p ≥ 0.5) differences in protein, ash, fat, crude fibre, moisture and carbohydrate, vitamin A, vitamin C, potassium and sodium contents.

Akindahusi AA, Salawu SO (2005). Phytochemical screening of nutrient and anti-nutrient composition of selected tropical green leafy vegetable. Afr j biotechnol. 4: 492-581.

Akinyeye RO, Oluwadunsin A, Omoyeni A (2011). Proximate, mineral, anti-nutrients, phyto-chemical screening and amino acid compositions of the leaves of Pterocarpus mildbraedi Harms. Elec J Env Agricult Food Chem.10

Akubugwo IE, Obasi NA, Chinyere GC, Ugbogu AE (2007). Nutritional and chemical value of Amaranthus hybridus L. leaves from Afikpo, Nigeria. Afr J Biotechnol. 6.

Indexed at, Google Scholar, Cross Ref

Asaolu SS, Adefemi OS, Oyakilome IG, Ajibulu KE, Asaolu MF (2012). Proximate and mineral composition of Nigerian leafy vegetables. J Food Res.1: 214.

Indexed at, Google Scholar, Cross Ref

Ekpo AS (2007). Determination of chemical composition of Gnetum Africanium (AFANG) seeds. Pak J Nutr. 6: 140 - 143.

Indexed at, Google Scholar, Cross Ref

Iheanacho KM, Udebuani AC (2009). Nutritional composition of some leafy vegetables consumed in Imo state, Nigeria. J Appl SCI Environ. 13.

Indexed at, Google Scholar, Cross Ref

Mensah JK, Okoli RI, Ohajuobodo JO, Elfidlyl K (2008). Phyto-chemical, Nutritional and medicinal properties of some leafy vegetables consumed by Edo people of Nigeria. Afr J Biotechnol. 7: 2305-2308.

Ogunlada IA, Ilugbiyin A, Osasona AI (2011). Proximate, mineral, anti-nutrient, phyto-chemical screening and Amino acid compositions of leaves of pterocarpus mildbraedi Harms. Elec J Env Agricult Food Chem. 9: 1322-1333.

Okerulu I, Onyema C (2015). Comparative assessments of photochemical, proximate and elemental composition of Gnetum Africanum (Okazi) Leaves. Am J Analyt Chem. 6: 604-609.

Orwa C, Mutua A, Kindt R, Tamnadass R, Anthony S (2009). Agroforestree database: A tree reference and selection guide version 4.

Pasch A (2006). The regulation of potassium balance. In Forum Med Suisse. 6: 468-473.

Prentice GA, Langridge EW (1992). Laboratory control in milk product manufacture. Publishers, New York.1-49.

Citation: Amonyeze AO et al., (2022). Okazi (Gnetum africanum) manually operated leaf slicer: Design, fabrication and performance evaluation. AJFST. 13: 021.