Research - African Journal of Food Science and Technology ( 2024) Volume 15, Issue 1

Received: 28-Dec-2023, Manuscript No. AJFST-23-123819; , Pre QC No. AJFST-23-123819; , QC No. AJFST-23-123819; , Manuscript No. AJFST-23-123819; Published: 23-Jan-2024

This study focused on the chemical and nutritional assessment of cookies prepared from blends of pigeon peas (Cajanus cajan) and bambara groundnuts (Vigna subterranean L. Verdc) flours, in combination with wheat (Triticum aestivum) flour at varying proportions. Proximate composition analysis included moisture, ash, crude fiber, fat, protein, and carbohydrate content determination. Sensory attributes such as taste, flavor, crispness, texture, color, and overall acceptability were evaluated using a 9-point hedonic scale. Statistical analyses were conducted through ANOVA, and mean separation was performed using Fisher's LSD and Turkey methods. The proximate composition of the developed cookies exhibited varying ranges: moisture (0.31% to 2.07%), ash (1.03% to 3.29%), crude fiber (0.08% to 3.71%), fat (3.05% to 4.80%), protein (6.42% to 15.32%), and carbohydrate (74.40% to 87.36%). Sensory attributes, including taste (6.07% to 8.37%), flavor (5.77% to 7.93%), crispness (7.23% to 7.77%), texture (7.37% to 7.93%), color (6.10% to 8.27%), and overall acceptability (6.67% to 8.03%), demonstrated diverse responses among the cookie samples.

Cookies made from 100% wheat flour displayed lower moisture, ash, crude fiber, and protein content, while exhibiting higher fat and carbohydrate contents. Additionally, they outperformed in terms of taste, flavor, color, texture, crispness, and overall acceptability. Conversely, cookies produced from 100% pigeon pea flour showed elevated ash, crude fiber, and protein content, with lower ratings in taste, flavor, crispness, color, and overall acceptability. This research highlights the potential for incorporating pigeon peas and bambara groundnuts in baked products to enhance the nutritional profile of wheat flour cookies. The recommended audience for these cookies includes children, youth, young adults, and the elderly, owing to their nutritional benefits. The findings contribute to promoting the utilization of these crops and diversifying baked goods for improved nutritional value.

Cookies, Crispiness, Flavor, Pigeon Peas, Bambara Groundnuts.

Legume seeds constitute significant sources of proteins, comprising approximately 30% of their total composition (Juárez-Chairez et al., 2022). The protein content can vary between 20% and 45%, with essential amino acids like lysine being particularly abundant. The protein levels are influenced by the type of plant and cultivation conditions, with peas and beans containing 17-20% proteins, while lupins and soybeans exhibit higher levels ranging from 38-45% (Maphosa & Jideani, 2017). In many Low-Income Food Deficit Countries (LIFDCs), grain legumes serve as the primary dietary protein source for a substantial portion of the population (Belete, 2022). Various legumes, such as bambara groundnuts, lima beans, cowpea, and soybeans, play crucial roles in the diets of people in Africa and Asia, providing essential nutrients such as protein, calories, vitamins, and minerals (Majili et al., 2022). Notable legumes commonly consumed include pigeon pea, kidney beans, black gram, chickpeas, green gram, and lentils (Majili et al., 2022).

Pigeon pea (Cajanus cajan), also known as dhal, red gram, or tur, is an erect perennial legume shrub belonging to the Fabaceae family. It thrives in heat-tolerant conditions and is often cultivated as an annual crop, reaching heights of 91-366 cm (Balida et al., 2022). Originating in the Indian subcontinent over 3500 years ago, pigeon pea is currently grown in subtropical and tropical regions worldwide (Odeny, 2017). Tanzania ranks as the fourth-largest global producer of pigeon pea, with key production regions including Arusha, Dodoma, Manyara, Lindi, and Mtwara (Mponda et al., 2014). Pigeon pea is rich in vitamins, particularly riboflavin, thiamine, choline, and niacin, all of which are water-soluble (Olagunju et al., 2018). It also serves as a source of crude protein (22-27%), dietary fiber, and antioxidants, impacting various aspects of human health, including blood pressure regulation, growth and development, anemia prevention, and immune system support (Olagunju et al., 2018). Bioactive compounds present in pigeon pea contribute to modulating the natural gut microbiota, thereby reducing inflammation (Talari & Shakappa, 2018).

Bambara groundnut (Vigna subterranean L. Verdc) is an African-origin legume crop utilized locally as a vegetable or snack. Renowned for its adaptability, bambara nut thrives in harsh conditions and is considered one of the most drought-resistant grain legumes. The seeds are valued for their balanced nutritional profile, containing high levels of iron, lysine, and methionine in the protein, making them a resilient option for cultivation in regions with annual rainfall below 500 mm (Maphosa et al., 2022). Bambara groundnut exhibits resistance to high temperatures and can flourish in poor marginal soils unsuitable for other leguminous crops. The seeds boast a well-balanced composition for human nutrition, containing 20% soluble carbohydrates and 8% fats (Mashau et al., 2022).

A cookie, a popular snack, is typically a thin, flat, crispy, or cake-like pastry with a sweet flavor, baked or fried. Common ingredients include flour, sugar, and some form of fat or oil, with additional components like raisins, oats, almonds, or chocolate chips (Adeyanju et al., 2022). Cookies may be baked until crisp or just long enough to remain warm, and the degree of softness depends on the cooking duration (Adegbanke et al., 2019). Becoming a beloved fast food product across all age groups, cookies are favored for their portability, taste, cholesterol-free nature, and affordability (Soares et al., 2023). Cookies can be crafted from hard dough, hard sweet dough, or soft dough, and they may be enriched or fortified with various ingredients to meet specific nutritional or therapeutic needs of consumers.

Pigeon pea stands out as a valuable crop with significant nutritional benefits, offering an economical source of essential nutrients crucial for human health. Despite its nutritional advantages, pigeon pea remains underutilized, often regarded as food for the economically disadvantaged (Adenekan et al., 2017). Moreover, there has been limited focus on research and development to unlock the full potential of pigeon pea as a versatile ingredient. Recognizing the untapped possibilities, pigeon pea can be effectively integrated into various food products, such as cookies, biscuits, noodles, pasta, and restructured meats like sausages, bringing a novel and nutritious dimension to these items. The incorporation is justified by pigeon pea's notable characteristics, including high fiber and protein content, gluten-free status, a low glycemic index, significant antioxidant levels, and functional properties such as fat absorption and water-binding capacity (Balida et al., 2022).

In parallel, bambara groundnut, considered the third most crucial grain legume in semi-arid Africa, following groundnut (Arachishypogaea L.) and cowpea (Vigna unguiculata), has received insufficient research attention to harness its full potential (Adegbanke et al., 2019). Utilizing bambara groundnuts in combination with pigeon pea flour presents an opportunity to enhance the chemical and mineral composition of cookies, thereby elevating the nutritional value of these food items. The overarching objective is to address the underutilization of pigeon pea and the limited research on bambara groundnut by exploring their potential synergy in the production of cookies. This research aims to contribute valuable insights that can stimulate increased production, utilization, and marketing of pigeon pea and bambara groundnuts. Ultimately, such advancements can have a positive impact on the income and well-being of farmers in the country, aligning with broader efforts to promote sustainable agriculture and improve overall nutritional standards.

Study area

The research was carried out at Sokoine University of Agriculture in Morogoro, Tanzania. The process of preparing cookies took place in the food science bakery area. The determination of proximate composition was conducted in the laboratories of both the Department of Food Science and Agro-processing and the Department of Animal, Aquaculture, and Range Science. Subsequently, the sensory evaluation phase occurred at the dedicated sensory evaluation laboratory.

Materials

The acquisition of dried pigeon peas and Bambara groundnut seeds occurred through a purchase from Kigoma market. Meanwhile, wheat flour, sugar, margarine, vanilla essence, and baking powder were sourced from local markets in Morogoro.

Methods

The study employed an experimental research design to investigate the acceptability of cookies by consumers and analyze the proximate composition of the cookies. A one-way analysis of variance (ANOVA) was utilized, and significant differences were considered at a 95% confidence interval (p < 0.05). The primary factors for testing consumer acceptability were the sensory attributes of cookies, including color, taste, flavor, crispness, and texture, assessed on a 9-point hedonic scale.

Preparation of flours

The process of preparing Bambara groundnuts flour involved a series of steps. Initially, the groundnuts were subjected to cleaning, washing, and soaking for 30 minutes. Following this, they were boiled for 25 minutes, dried for a period of 10 hours, dehulled, milled into flour, and finally packaged in airtight containers for future use. On the other hand, the preparation of pigeon pea flour began with cleaning and soaking the grains in water for an extended period of 38 hours. Subsequently, manual dehulling was carried out on the soaked grains. After loosening the seeds, they were washed and left to sundry. Once dried, the grains were milled into flour and, like the bambara groundnuts flour, packaged in airtight containers until they were ready to be utilized.

Formulation or blends combination used for the preparation of the cookies

For the formulation of cookies, three composite flours were created by combining wheat flour, pigeon pea flour, and bambara groundnuts flour in various ratios. The blends were as follows: 100:0:0, 0:100:0, 50:50:0, 30:35:35, and 20:60:20 (Table 1).

| Sample | Pigeon pea flour (%) | Wheat flour (%) | Bambara groundnuts flour (%) |

|---|---|---|---|

| W | 0 | 100 | 0 |

| P | 100 | 0 | 0 |

| PW | 50 | 50 | 0 |

| PB | 35 | 30 | 35 |

| PWB | 60 | 20 | 20 |

Cookies preparation

The cookie preparation process began with a fundamental formulation based on 1 kilogram of flour or blends. This flour mixture was combined with an equal quantity of other active components, including sugar, baking powder, water, fat, and vanilla flavor. The fats and sugar were creamed together until achieving a light and fluffy consistency. Subsequently, the remaining dry ingredients were added, followed by the gradual incorporation of water until the desired batter texture was achieved. To attain the appropriate thickness, the batters underwent kneading on a rolling table. Using a biscuit cutter, the batters were then shaped into the desired forms. Baking took place for a duration of 15-25 minutes on baking trays at 180°C in an oven. Once baked, the cookies were allowed to cool before being packaged in low-density polythene bags. They were stored at room temperature until subjected to later evaluation.

Notably, during production, it was observed that sample W exhibited a lighter brown color in comparison to samples PW, PB, and PWB. This color difference was attributed to the increasing proportion of composite flour, causing the cookies to adopt a darker hue. Additionally, sample P displayed an unattractive color during the production process (Table 2).

| Sample | Pigeon pea flour (%) | Wheat flour (%) | Bambara groundnuts flour (%) | Fat (g) | Sugar (g) | Baking powder (g) | Vanilla flavor (teaspoonful) | Water (ml) |

|---|---|---|---|---|---|---|---|---|

| W | 0 | 100 | 0 | 300 | 300 | 10 | 2 | 650 |

| P | 100 | 0 | 0 | 300 | 300 | 10 | 2 | 650 |

| PW | 50 | 50 | 0 | 300 | 300 | 10 | 2 | 650 |

| PB | 35 | 30 | 35 | 300 | 300 | 10 | 2 | 650 |

| PWB | 60 | 20 | 20 | 300 | 300 | 10 | 2 | 650 |

Proximate composition determination of the developed cookies

The analysis of proximate composition was conducted using the AOAC methods (Nielsen. 2010) on duplicate samples. This approach was employed to determine the percentage of moisture, ash, protein, fat, crude fiber, and carbohydrate content in the samples.

Moisture content determination

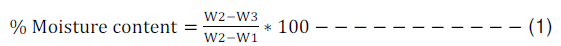

The determination of moisture content involved the following procedure: Initially, 2 g of the samples were weighed into a dry petri dish with a known mass. Subsequently, the samples were dried in an oven at a temperature of 105ºC for a duration of 3 hours. After the drying process, the samples were allowed to cool to room temperature, and their final weight, along with the petri dish, was measured using an electronic analytical balance.

The difference in mass, representing the weight of moisture lost, was calculated using the formula:

Where:

W1 = weight of the empty petri dish,

W2 = weight of the petri dish + sample before drying,

W3 = weight of the petri dish + sample after drying.

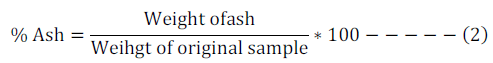

Ash content determination

The determination of ash content involved the following procedure: Initially, 2 g of the samples were weighed into a pre-weighed crucible. Subsequently, the crucible with the samples was heated in a moisture extraction oven, also known as a muffle furnace, at a temperature of 600°C for a period of 6 hours to facilitate the ashing process. These continued until the samples turned white and were free of carbon. Following the incineration, the samples were removed from the furnace, allowed to cool in a desiccator to room temperature, and immediately reweighed.

The weight of the ash (residual ash) was then calculated using the formula:

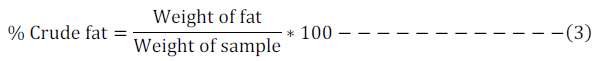

Crude fat determination

The determination of crude fat involved the utilization of the solvent extraction method as per AOAC (2000). The procedure was as follows: Two grams of each sample were accurately weighed and gently packed into a fat-free extraction thimble, secured with cotton wool. This thimble was then fitted with a reflux condenser and placed in the soxhlet extraction unit with a reflux condenser.

A Soxhlet flask (250 ml) was prepared by drying it in the oven and cooling it in the desiccator. Petroleum ether, with a boiling point between 40ºC and 60ºC, was added to the flask, constituting 34% of the flask's volume. The Soxhlet flask, extractor, and condenser set were then placed on the heater for 1 hour, with constant water flow from the tap to condense the ether vapor. During this time, fat was extracted for 1 hour using the petroleum ether, and the recovered fat was obtained through distillation.

After evaporating the solvent, the flask was dried in the oven at 105°C, cooled to room temperature, and reweighed to determine the extracted lipid's mass. The mass of the oil extracted was determined by difference and expressed as follows:

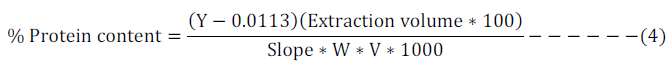

Crude protein determination

For the determination of crude protein, the Lowry method was employed, which involves the combination of the biuret reagent with the Folin-Ciocalteau phenol reagent. This reaction specifically targets tyrosine and tryptophan residues in proteins, producing a bluish color that can be measured within the range of 500 - 750 nm, depending on the required sensitivity. The procedure involved the careful weighing of 0.5 grams of each sample, which was then placed in extraction bottles. To dissolve the solid samples, 1 ml of NaOH and 50 ml of distilled water were added to each sample. The mixture was shaken in a water bath for 30 minutes, filtered, and 5 ml of the resulting solution were transferred to test tubes.

Subsequently, 7 ml of the Lowry solution, comprising solution A (Na2CO3 + NaOH), solution B (CuSO4), and solution C (Tartaric acid), was added to the samples. The mixture was incubated for 30 minutes. Following this, 1 ml of Folin solution was introduced into the samples, and the mixture underwent another 30-minute incubation period. The absorbance of each sample was then measured at 710 nm.

The calculation of protein content (% protein) was determined using the formula:

Where:

Y = Actual absorbance at 710 nm.

0.0113 = Y-intercept from the graph of absorbance at 710 nm against concentrations (mg/ml).

Extraction volume = Volume of distilled water (50 ml).

Slope = Slope obtained from the graph of absorbance at 710 nm against concentrations (mg/ml) (0.5374).

W = Sample weight (0.5 g).

V = Analytical volume (1 ml).

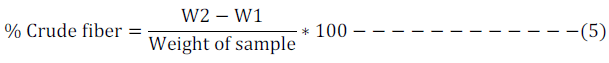

Crude fiber determination

The determination of crude fiber followed the AOAC (2000) method and involved the following steps:

Initially, 2 grams of samples were accurately weighed and then defatted. The defatted samples were boiled for 30 minutes under reflux in a 600 ml long beaker. Subsequently, 200 ml of hot 1.25% H2SO4 solution was added to the beaker to hydrolyze carbohydrates and proteins. After this process, the filtrate was passed through filter papers, and the residue was washed with hot water until it reached a neutral state. The residue was then transferred to the beaker, and 200 ml of NaOH was added. The beaker was returned to the digesting apparatus, boiled, and refluxed for 30 minutes to effect the saponification of fat. The resulting filtrate was filtered and washed with hot water until it was neutral. The washed residue was allowed to drain dry before being transferred to a pre-weighed crucible and dried in an oven at 105°C to achieve a constant weight. Subsequently, the residue was placed in the crucible, dried at 100°C overnight, and then subjected to a muffle furnace at 600°C for 3 hours. Finally, it was cooled in a desiccator and reweighed.

The calculation of % Crude Fiber was done using the formula:

Where:

W1 = Weight of the crucible + sample as ash (i.e., crucible + ash)

W2 = Weight of the crucible + sample after boiling, washing, and drying

Carbohydrate content determination

For the determination of carbohydrate content, the nitrogen-free method outlined by AOAC (2000) was employed. Carbohydrate content was calculated as the weight difference between 100 and the sum of other proximate parameters, referred to as Nitrogen-Free Extract (NFE) percentage carbohydrate. The formula used for this calculation was:

% Carbohydrate (NFE)} = 100 - (M + P + F + A + F2) (6)

Where:

M = Moisture

P = Protein

F = Fat

A = Ash

F2 = Crude fiber

Evaluation of Sensory Attributes and Acceptability of the Developed Cookies

In the consumer study, thirty untrained panelists, consisting of both staff and students, participated. Each panelist received sensory evaluation forms, and the samples were presented on white paper plates, each labeled with random three-digit codes. To mitigate bias, panelists were explicitly instructed to taste each sample in the specified sequence. Between samples, they were provided with drinking water to cleanse their palates. The cookies underwent judgment on a 9-point hedonic scale, where a rating of 9 signified "like extremely," 8 represented "like very much," 7 denoted "like moderately," 6 indicated "like slightly," 5 reflected "neither like nor dislike," 4 suggested "dislike slightly," 3 conveyed "dislike moderately," 2 expressed "dislike very much," and 1 conveyed "dislike extremely." This scale aimed to assess the degree of preference for five sensory attributes: taste, flavor, crispness, texture, color, and overall acceptability.

Statistical Analysis

The data were analyzed using the Statistical Package for Social Sciences (SPSS) version 16.0 for Windows. Analysis of variance (ANOVA) was employed, and the results were summarized using the Microsoft Excel Package of 2010. This approach was utilized to identify differences in sample means. The treatment means were further separated through the application of Fisher's Least Significant Difference (LSD) test and the Turkey method, both at a significance level of 5%.

Proximate composition of the developed cookies

The proximate compositions of the developed cookies are detailed in (Table 3). At the 5% level of significance, significant differences were observed in the proximate compositions among the various cookie samples.

| Samples | Composition (%) | |||||

|---|---|---|---|---|---|---|

| Moisture | Ash | Fibre | Fat | Protein | Carbohydrate | |

| W | 0.31 ± 0.07a | 1.03 ± 0.28a | 0.08 ± 0.01a | 4.80 ± 0.34a | 6.42 ± 0.13a | 87.36 ± 0.25a |

| P | 1.06 ± 0.06b | 3.29 ± 0.14b | 1.12 ± 0.01b | 4.50 ± 0.21a | 14.03 ± 0.68b | 76.01 ± 0.83b |

| PW | 1.61 ± 0.16c | 2.19 ± 0.11c | 2.10 ± 0.00c | 4.38 ± 0.21a | 15.22 ± 0.14b | 74.40 ± 0.27bc |

| PB | 0.65 ± 0.20ab | 2.15 ± 0.03c | 1.94 ± 0.01c | 3.05 ± 0.03b | 15.32 ± 0.43b | 77.18 ± 0.24bd |

| PWB | 2.07 ± 0.28c | 2.64 ± 0.27c | 3.71 ± 0.34d | 3.19 ± 0.04b | 11.64 ± 0.03c | 76.75 ± 0.66bd |

Values were mean ± standard deviation of duplicate determinations, n=5. Samples with different superscripts within the same column were significantly (P≤0.05) different.

Legend: W = 100% Wheat flour; P = 100% Pigeon pea flour; PW = 50%:50% Pigeon pea flour and Wheat flour; PB = 35%:30%:35% Pigeon pea flour, wheat flour and Bambara groundnuts flour; PWB = 60%: 20%:20% Pigeon pea flour, wheat flour and Bambara groundnuts flour.

Moisture content

The moisture content of cookies plays a crucial role in determining their quality and shelf life. Maintaining an optimal moisture level is essential for achieving the desired texture and preventing issues such as mold growth or excessive dryness (Adeniyi et al., 2014). Cookies with higher moisture content, exceeding 10%, are generally softer but more susceptible to mold. Conversely, those with lower moisture content, below 10%, may become dry and less appealing to consumers. In our study, the moisture contents of the developed cookie samples were found to range from 0.31% to 2.07%. Notably, cookies made with 100% wheat flour (W) exhibited the lowest moisture content at 0.31%. This lower moisture level may contribute to a drier and crispier texture, a characteristic that could be attributed to the higher gluten content in wheat flour, which has waterbinding properties.

Contrastingly, the cookie made with 100% pigeon peas flour (P) displayed a higher moisture content of 1.06%, suggesting a softer and moister product. The cookies crafted from a blend of 50% pigeon peas and 50% wheat flour (PW) had a moisture content of 1.61%, falling between the extremes of the pure wheat (W) and pure pigeon peas (P) cookies. Further, the cookie prepared with a composite flour of 35% pigeon peas, 30% wheat flour, and 35% bambara groundnuts flour (PB) exhibited a moisture content of 0.65%. This composition may contribute to a drier and crumbly texture, particularly due to the higher proportion of wheat flour in the blend.

Interestingly, cookies made with a composite flour of 60% pigeon peas, 20% wheat flour, and 20% bambara groundnuts flour (PWB) showed the highest moisture content at 2.07%. This high moisture level suggests a softer and moister cookie, emphasizing the impact of the higher proportion of pigeon peas flour in influencing the final product's texture. These findings highlight the importance of considering flour composition in achieving the desired moisture content and texture in cookies.

Ash content

Ash content serves as a metric for determining the total mineral content in food, encompassing essential minerals such as calcium, iron, and phosphorus. The composition of flours used in cookie formulation can influence the ash content, leading to variations in mineral concentrations (Sanni et al., 2016). In our study, cookies crafted with 100% wheat flour (W) exhibited the lowest ash content at 1.03%, implying a relatively lower mineral content compared to other variants. Conversely, cookies prepared with 100% pigeon peas flour (P) showed the highest ash content at 3.29%, indicating a higher mineral concentration attributable to the nature of pigeon peas flour.

For cookies formulated with a composite flour of 50% pigeon peas and 50% wheat flour (PW), the ash content was measured at 2.19%, positioning it between the pure pigeon peas (P) and wheat (W) cookies in terms of mineral content. Cookies made with a blend of 35% pigeon peas, 30% wheat flour, and 35% bambara groundnuts flour (PB) displayed an ash content of 2.15%, signifying a moderate mineral content resulting from the combination of these ingredients. Interestingly, cookies prepared with a composite flour of 60% pigeon peas, 20% wheat flour, and 20% bambara groundnuts flour (PWB) demonstrated an ash content of 2.64%. This higher ash content suggests a relatively greater mineral concentration, primarily influenced by the higher proportion of pigeon peas flour in the blend. It is noteworthy that a higher mineral content has been associated with an increase in ash content (Dada et al., 2012).

Ash, as the inorganic residue remaining after the removal of water and organic matter through heating in the presence of an oxidizing agent, is used to identify mineral elements in food (Sanni et al., 2016). The observed variations in ash content among the cookies highlight the importance of flour composition in influencing the mineral profile of the final product.

Fiber content

Crude fiber content in cookies refers to the indigestible portion of plant-based foods, encompassing cellulose, hemicelluloses, and lignin (Groff et al., 2015). In our study, cookies crafted with 100% wheat flour (W) displayed the lowest crude fiber content at 0.08%, consistent with the lower fiber content inherent in wheat flour compared to legume-based flours. Contrastingly, cookies made with 100% pigeon peas flour (P) exhibited a higher crude fiber content of 1.12%, emphasizing the significant contribution of pigeon peas flour to the cookie's fiber content compared to wheat flour. The cookies formulated with a composite flour of 50% pigeon peas and 50% wheat flour (PW) had a crude fiber content of 2.10%, surpassing the content of the 100% wheat flour cookie but falling short of the one made with 100% pigeon peas flour.

Moreover, cookies prepared with a composite flour of 35% pigeon peas, 30% wheat flour, and 35% bambara groundnuts flour (PB) demonstrated a moderate crude fiber content of 1.94%, indicating a balanced fiber contribution from the combination of these ingredients. Interestingly, cookies made with a composite flour of 60% pigeon peas, 20% wheat flour, and 20% bambara groundnuts flour (PWB) exhibited the highest crude fiber content at 3.71%, underscoring the influence of higher proportions of pigeon peas and bambara groundnuts flour on fiber content. Our findings differ from those reported by (Adeniyi et al. 2014), who noted a higher range of crude fiber content (5.31% to 7.05%). Discrepancies may arise from variations in crop varieties, processing methods, and flour blending techniques. The study's results highlight the impact of cereal and legume flour blending on fiber content in cookies. Blending wheat flour with pigeon peas flour (sample PW) increased the fiber content to 1.12%, while incorporating equal amounts of bambara groundnuts flour and pigeon peas flour (sample PB) led to a fiber content of 1.94%. Significantly, elevating the proportion of pigeon peas flour to 60% in the blend (sample PWB) resulted in a higher fiber content of 3.71%. The substantial fiber content in pigeon peas flour, as observed in our study, holds potential health benefits. Scientific studies suggest that crude fiber aids in weight management by promoting satiety, reducing energy intake, and contributing to weight loss. Additionally, it plays a vital role in maintaining internal pressure in the intestinal tract, facilitating smooth bowel movements, and preventing constipation (Groff et al., 2015). Moreover, fiber has been associated with lowering blood cholesterol levels and regulating blood glucose levels, making it particularly valuable for individuals with diabetes (Hamza et al., 2014).

In conclusion, our study underscores the nutritional significance of incorporating legume flours, particularly pigeon peas, into cereal-based products, showcasing their potential health benefits, especially for individuals with specific dietary requirements such as diabetic patients.

Fat content

The fat content in the developed cookies exhibited a range from 3.05% (PB) to 4.80% (W). Notably, cookies composed solely of 100% wheat flour (W) recorded the highest fat content at 4.80%. In comparison, the cookie made with 100% pigeon peas flour (P) had a slightly lower fat content of 4.50% than its wheat flour counterpart. As the percentage of pigeon peas flour increased in composite flours, there was a progressive decrease in fat content. This trend can be attributed to the inherent fat content variations among different flours, with wheat flour generally containing more fat than legume-based counterparts such as pigeon peas flour and bambara groundnuts flour. Consequently, cookies exclusively made from 100% wheat flour tend to exhibit higher fat content. Furthermore, the proportions of each type of flour utilized in the composite flours can significantly influence the overall fat content. For instance, a higher proportion of wheat flour, with its naturally higher fat content, contributes to an increased fat content in the resulting cookies. Additionally, the lower moisture content in cookies can lead to a higher concentration of fat.

Interestingly, our fat content results diverge from those reported by (Adeola et al. 2017), whose fat content ranged from 2.57% to 2.94%. This discrepancy may stem from the incorporation of specific proportions of pigeon pea and bambara groundnuts flours into wheat flour, coupled with the combined processing method employed, resulting in a decrease in fat content from sample W to PB. This observation underscores the potential impact of blending various flours on the nutritional profile of cookies, emphasizing the significance of such formulations in enhancing the nutritional value of cookies, particularly for children and other consumer groups across various age demographics.

Protein content

The protein content in the developed cookies exhibited a range from 6.42% to 15.32%. The cookie made with 100% pigeon peas flour (P) recorded the highest protein content at 14.03%. In contrast, cookies made exclusively with wheat flour (sample W, 100% wheat flour) exhibited the lowest protein content, registering at 6.42%. Composite flours that included pigeon peas flour consistently demonstrated higher protein content than those comprising wheat flour alone. For instance, the cookies made with a composite flour of 50% pigeon peas flour and 50% wheat flour (PW) exhibited a protein content of 15.22%. The cookies made with a composite flour of 35% pigeon peas flour, 30% wheat flour, and 35% bambara groundnuts flour (PB) had the highest protein content among other samples, reaching 15.32%. Meanwhile, cookies made with a composite flour of 60% pigeon peas flour, 20% wheat flour, and 20% bambara groundnuts flour (PWB) had a protein content of 11.64%.

The increase in protein content observed in the composite flours can be attributed to the higher percentage of pigeon peas flour in the mixture. Pigeon peas flour, being legume-based, generally contains more protein than wheat flour, contributing a substantial amount of protein to the composite flour and resulting in higher protein content in the cookies. Additionally, the processing methods employed in producing the flours and cookies may have influenced the protein content observed in the developed cookies. In countries like Tanzania, where protein malnutrition is prevalent, foods rich in protein content, such as pigeon peas and bambara groundnuts, hold significant nutritional importance (Mponda et al., 2014). The high crude protein content of pigeon pea flour suggests that the composite flour can serve as a low-cost protein source, particularly beneficial for populations facing protein deficiency. For infants aged 4 to 6 months, 7-9 months, and 10-12 months, nutritional recommendations indicate protein intake levels of 1.30 g/kg per day, 1.25 g/kg per day, and 1.15 g/ kg per day, respectively (Chandra et al., 2015). Proteins play a crucial role in children's growth and development, contributing to the formation of new tissues, repair of worn-out tissues, and acting as enzymes and hormones. Additionally, proteins maintain fluid, electrolyte, and acid– base balance, supporting a robust immune system. Proteins also serve as carriers for essential nutrients, including lipids, vitamin A, iron, sodium, and potassium (Mponda et al., 2014).

Carbohydrate content

The carbohydrate contents of the cookies varied, with values ranging from 74.40% in sample PW (cookies made from a 50%:50% blend of pigeon pea flour and wheat flour) to 87.36% in sample W (cookies made from 100% wheat flour). Notably, cookies made with 100% wheat flour (W) exhibited the highest carbohydrate content (87.36%). This outcome is consistent with the composition of wheat flour, which is predominantly composed of carbohydrates, leading to the higher carbohydrate content in cookies made exclusively from wheat flour. Cookies crafted from composite flours that included pigeon peas flour, such as those made with a blend of 50% pigeon peas flour and 50% wheat flour (PW), demonstrated comparatively lower carbohydrate content (74.40%) than those made with wheat flour alone. Cookies exclusively made from 100% pigeon peas flour (P) had a carbohydrate content of 76.01%, which was lower than that observed in cookies made from the composite flour of 35% pigeon peas flour, 30% wheat flour, and 35% bambara groundnuts flour (PB), as well as those made from the composite flour of 60% pigeon peas flour, 20% wheat flour, and 20% bambara groundnuts (PWB), registering carbohydrate contents of 77.18% and 76.75%, respectively. The marginal variations in carbohydrate content among cookies with different composite flours may be attributed to pigeon peas flour containing relatively less carbohydrate and more protein, contributing to the lower carbohydrate content in cookies made exclusively from 100% pigeon peas flour.

Although significant differences in carbohydrate contents were observed among the cookies samples, a general trend indicated that the percentage of carbohydrate decreased with an increase in the proportion of pigeon peas flour. This trend was evident in cookies like PWB, made with a composite flour of 60% pigeon peas flour, 20% wheat flour, and 20% bambara groundnuts flour, which exhibited a carbohydrate content of 76.75%, compared to cookies like PB, crafted from a composite flour of 35% pigeon peas flour, 30% wheat flour, and 35% bambara groundnuts flour, which had a slightly higher carbohydrate content of 77.18%. These findings underscore pigeon pea and bambara groundnuts flour as noteworthy sources of carbohydrates (Wanjiku et al., 2022).

Sensory attributes and acceptability of the developed cookies

The sensory attributes of developed cookies were presented in (Table 4). The sensory rating for taste, flavor, crispness, texture, colour and overall acceptability of the cookies samples ranged from 6.07 to 8.37%, 5.77 to 7.93%, 7.23 to 7.77%, 7.37 to 7.93%, 6.10 to 8.27% and 6.67 to 8.03% respectively.

| Samples | Taste | Flavor | Crispness | Texture | Colour | Overall acceptability |

|---|---|---|---|---|---|---|

| W | 8.37 ± 0.81a | 7.93 ± 1.05a | 7.60 ± 1.71a | 7.37 ± 1.56a | 8.27 ± 1.05a | 8.03 ± 1.03a |

| P | 6.07 ± 2.24b | 5.77 ± 1.94b | 7.23 ± 1.25a | 7.43 ± 1.07a | 6.10 ± 2.50b | 6.67 ± 1.52b |

| PW | 7.33 ± 1.85a | 7.50 ± 1.57a | 7.40 ± 1.52a | 7.63 ± 1.25a | 7.83 ± 1.18a | 7.57 ± 1.22a |

| PB | 7.87 ± 1.01a | 7.53 ± 1.01a | 7.77 ± 1.14a | 7.80 ± 0.93a | 7.93 ± 1.17a | 7.87 ± 0.97a |

| PWB | 7.70 ± 1.12a | 7.60 ± 0.97a | 7.67 ± 1.21a | 7.93 ± 1.08a | 7.93 ± 1.05a | 7.87 ± 0.94a |

Values were mean ± standard deviation of duplicate determinations, n=5. Samples with different superscripts within the same column were significantly (P≤0.05) different.

Legend: W = 100% Wheat flour; P = 100% Pigeon pea flour; PW = 50%:50% Pigeon pea flour and Wheat flour; PB = 35%:30%:35% Pigeon pea flour, wheat flour and Bambara groundnuts flour; PWB = 60%: 20%:20% Pigeon pea flour, wheat flour and Bambara groundnuts flour.

Taste

The taste of cookies ranged from 6.07% to 8.37%, with significant differences noted between cookies made from 100% P and other samples. Cookies made from 100% W, PW, PB, and PWB received high taste ratings (approximately 8.0), suggesting a favorable taste attributed to the familiar flavor of wheat, balanced profiles in PW, and the introduction of bambara groundnuts in PB and higher pigeon peas content in PWB. The findings are in line with other previous studies carried out (Mshau et al., 2022).

Flavor

Flavor scores ranged from 5.77% to 7.93%, with cookies made from 100% W, PW, PB, and PWB being highly liked (approximately 8.0). Familiarity with wheat flavor, balanced profiles in PW, and the introduction of bambara groundnuts in PB and higher pigeon peas content in PWB contributed to favorable flavor scores. Cookies made from 100% P received a slightly liked score (approximately 6.0), potentially due to its unique and less familiar flavor (Majili et al., 2022).

Crispiness

Crispiness scores ranged from 7.23% to 7.77%, with no significant differences observed between the cookie samples. Cookies made from 100% W, PB, and PWB were very much liked (approximately 8.0), possibly due to the common use of wheat flour (Mponda et al., 2014). Cookies made with a blend of 50% P and 50% W and those from 100% P were moderately liked (score approximately 7.0).

Texture

Texture scores ranged from 7.37% to 7.93%, with cookies made from PW, PB, and PWB receiving very much liked scores (approximately 8.0). Combining pigeon peas and wheat flours in PW resulted in a pleasing texture, while the introduction of bambara groundnuts in PB and higher pigeon peas content in PWB likely contributed to a more enjoyable texture. Cookies made from 100% W and 100% P were moderately liked (score approximately 7.0). These results are correspondingly similar to the other previous studies by (Ikipeme et al. 2010) and (Mongi & Gomezulu 2022).

Color

Color scores ranged from 6.10% to 8.27%, with significant differences observed between cookies made from 100% P and other samples. Cookies made from 100% W, PW, PB, and PWB were very much liked (approximately 8.0), with the golden-brown color of wheat flour contributing to visual appeal (Majili et al., 2022). Cookies made from 100% P were slightly liked (score approximately 6.0), potentially due to a darker color resulting from high carbohydrate and protein contents.

Overall Acceptability

Overall acceptability scores ranged from 6.67% to 8.03%, with significant differences observed for cookies made from 100% P compared to other samples. Cookies made from 100% W, PW, PB, and PWB were very much liked (approximately 8.0), owing to the widespread acceptance of wheat flour. Cookies made from 100% P were moderately liked (score approximately 7.0), potentially due to the distinct taste and texture of pigeon peas flour. The findings are consistently in line with other studies previously conducted in other localities (Mihafu et al., 2019; Nems et al., 2022).

Cookies made from composite flours of different ratios (100%, 50:50%, 35:30:35%, and 60:20:20%) derived from blends of pigeon pea flour, wheat, and bambara groundnuts flours were successfully developed. The study findings revealed that cookies made from 100% wheat flour generally exhibited low moisture, ash, crude fiber, and protein contents but were high in fat and carbohydrate contents. Moreover, these cookies performed better in terms of taste, flavor, color, texture, crispness, and overall acceptability. On the contrary, cookies made from 100% pigeon peas flour had higher levels of ash, crude fiber, and protein content, but they received lower ratings in most sensory attributes, including taste, flavor, crispness, color, and overall acceptability. Blends incorporating pigeon peas, wheat flours, and bambara groundnuts flour showed moderate performance, with some variations performing better in specific attributes than others. These differences in ratings can be attributed to the distinct characteristics of the flours used, including taste, texture, and color.

The preference for cookies based on wheat flour might be influenced by its familiarity and widespread use in traditional cookie recipes. Additionally, the processing method may cause changes in the physical and chemical properties of the materials in blended foods, potentially altering sensory perceptions among consumers. This research highlights the potential for the inclusion of pigeon peas and bambara groundnuts in baked products, promoting the utilization of these crops and enhancing the nutritional value of wheat flour cookies. The study recommends substitutions of pigeon peas flour and bambara groundnuts flour in cookie formulations, particularly in the range of 35% to 60% for pigeon peas flour and not exceeding 20% for bambara groundnuts flour, to enhance sensory attributes and overall acceptability.

The cookies developed in this study are recommended for consumption by children, youth, young adults, and the elderly due to their nutritional benefits. However, it is important to note that a major limitation of this study was resource constraints, both in terms of time and materials. This limitation hindered the investigation of other aspects such as the determination of the shelf life of the developed cookies, making it challenging to ensure their stability over time.

Recommendations

Based on the results obtained from the proximate composition and sensory evaluation of the cookies developed from different flours, the following recommendations are made for future studies:

(i) Conduct an analysis of essential micronutrients such as iron, calcium, zinc, and vitamins to comprehensively understand the overall nutritional profile of each cookie variation. These nutrients play crucial roles in various physiological functions and contribute significantly to the overall nutritional quality of the cookies.

(ii) Determine the glycemic index of each cookie variation to assess their impact on blood glucose levels. This is particularly relevant for individuals with diabetes or those aiming to maintain stable blood sugar levels.

(iii) Conduct an analysis of anti-nutrients, which are substances that can reduce the nutritional values of food by diminishing the bioavailability, digestibility, and utilization of nutrients.

(iv) Perform microbiological tests on the developed cookies to evaluate their microbiological stability during storage. This is crucial for ensuring the safety and quality of the cookies over time.

Acknowledgements

The authors acknowledge the Ministry of Livestock and Fisheries Development in Tanzania for financial support extended to Rudia Joseph to carry this study.

Competing Interests

The authors declare that there are no competing interests that exist.

Adegbanke OR, Ojo-Uyi DO, Oluwajuyitan TD (2019). Application of bambara groundnut in the production of cookies. Food Sci Qual Manag 83: 56-60.

Indexed at, Google Scholar, Cross Ref

Adenekan KM, FadimuGJ, Odunmbaku LA, Oke EK (2017). Effect of isolation techniques on the characteristics of pigeon pea (Cajanus cajan) protein isolates. Food Sci Nutr. 6(1):26 – 30.

Indexed at, Google Scholar, Cross Ref

Adeola A. A, Shittu, T. A, Onabanjo, O. O, Oladunmoye, O. O. (2017). Evaluation of nutrient compostion, functional and sensory attributes of sorghum, pigeon pea and soyabean flour blend as complimentary foods in Nigeria. Agron Afr. 29: 47-58.

Indexed at, Google Scholar, Cross Ref

Aderonke AM, Fashakin JB, Ibironke SI (2014). Determination of mineral content, proximate compostion and functional properties of complementary diets prepared from maize, soybean and pigeon pea. J Nutri Food Sci. 7: 53-56.

Indexed at, Google Scholar, Cross Ref

Adeyanju JA, Ogunlakin GO, Oloyede AA, Amure EA (2022). Optimisation of process variables for the production of cookies from wheat, fonio, pigeon pea flour blends using d–optimal design. Ann Fac Eng Hunedoara. 20(4): 101-106.

Balida LA, Regalado JT, Teodosio JJ, Dizon KA, Sun Z, et al.(2022). Antibiotic Isoflavonoids, Anthraquinones, and Pterocarpanoids from pigeon pea ( Cajanus cajan L.) Seeds against multidrug-resistant Staphylococcus aureus. Metabolites. 12(4): 279.

Indexed at, Google Scholar, Cross Ref

Chandra S, Singh S, Kumari D (2015). Evaluation of functional properties of composite flours and sensory attributes of composite flour biscuits. J Food Sci Tehnol. 52: 3681-3688.

Indexed at, Google Scholar, Cross Ref

Dada M, Nwawe CN, Okere RA, Uwubanmwen IO (2012).Potentials of Date Palm Tree to the Nigerian Economy. World J Agric Sci. 8(3): 309-315.

Emmanuel CI, Osuchukwu NC, Oshiele L (2010). Functional and Sensory Properties of Wheat (Aestium triticium) and Taro Flour (Colocasia esculenta) Composite Bread. Afr J Food Sci. 4(5): 248-253.

Indexed at, Google Scholar, Cross Ref

Gichohi-Wainaina WN, Mremi R, Chande M, Msuya JM, Kumwenda NC, et al. (2022). Drivers of Pigeon pea consumption among school-aged children in central Tanzania. Front Sustain Food Syst. 5: 726404.

Indexed at, Google Scholar, Cross Ref

Groff JL, Gropper SS, Hunt SM (2015). Advanced nutrional and human metabolism. 2nd edition. New York, 221-362.

Juárez-Chairez MF, Meza-Márquez OG, Márquez-Flores YK, Jiménez-Martínez C (2022). Potential anti-inflammatory effects of legumes: A review. Br J Nutr. 128(11): 2158–2169.

Indexed at, Google Scholar, Cross Ref

Kuraz Abebe B (2022). The dietary use of pigeon pea for human and animal diets. Sci World J. 2022.

Indexed at, Google Scholar, Cross Ref

Majili Z, Nyaruhucha CN, Kulwa K, Mutabazi K, Rybak C (2022). Identification and prioritization of pigeon pea-based products tailored to consumer preference perspective: A mixed method assessment approach. Legum Sci. 4(3):1 - 12.

Indexed at, Google Scholar, Cross Ref

Maphosa Y, Jideani VA (2017). The Role of Legumes in Human Nutrition. J Agric Food Sci. 1:13.

Indexed at, Google Scholar, Cross Ref

Maphosa Y, Jideani VA, Maphosa L (2022). Bambara groundnut production, grain composition and nutritional value: Opportunities for improvements. J Agric Sci. 160(6):448-458.

Indexed at, Google Scholar, Cross Ref

Mashau ME, Mukwevho TA, Ramashia SE, Siwela M (2022). The influence of Bambara groundnut (Vigna subterranean) flour on the nutritional, physical and antioxidant properties of steamed bread. CyTA J Food. 20(1): 259-270.

Indexed at, Google Scholar, Cross Ref

Mihafu FD, Issa JY, Kamiyango MW (2019). Implication of sensory evaluation and quality assessment in food product development, a review. Curr. Res. Nutr Food Sci. 8(3): 690 - 702.

Indexed at, Google Scholar, Cross Ref

Mongi RJ, Gomezulu AD (2022). Descriptive sensory analysis, consumer acceptability and conjoint analysis of beef sausages prepared from pigeon pea protein binder. Heliyon. 8: e10703.

Indexed at, Google Scholar, Cross Ref

Mponda O, Kidunda B, Bennett B, Orr A, Mausch K (2014). A Value Chain Analysis for Pigeon Pea in the Southern Regions of Tanzania Socioeconomics Discussion Paper Series Number 17. Int J Agric. 10(7): 39 – 45.

Nems A, Miedzianka J, Kita A (2022). Quality and nutritional value of cookies enriched with plant-based protein preparations. J Sci Food Agric. 102(11): 4629-4639.

Indexed at, Google Scholar, Cross Ref

Odeny DA.(2007). The potential of pigeonpea (Cajanus cajan (L.) Millsp.) in Africa.Nat Resour Forum. 31(4): 297-305.

Indexed at, Google Scholar, Cross Ref

Olagunju AI, Omoba OS, Enujiugha VN, Alashi AM, Aluko RE (2018). Pigeon pea enzymatic protein hydrolysates and ultrafiltration peptide fractions as potential sources of antioxidant peptides: An in vitro study. Lwt. 97:269-278.

Indexed at, Google Scholar, Cross Ref

Peter Ikechukwu A, Okafor DC, Kabuo NO, Ibeabuchi JC, Odimegwu EN, et al. (2017). Production and evaluation of cookies from whole wheat and date palm fruit pulp as sugar substitute. Int J Eng Technol Manag Appl Sci. 4(04): 1-31.

Sanni LO, Adebowale AA, Filani TA, Oyewole OB, Westby A (2006). Quality of flash and rotary dried fufu flour. J Food Agric Environ. 4(3and4):74-78.

Soares ID, Cirilo ME, Junqueira IG, Vanin FM, Rodrigues CE (2023). Production of Cookies Enriched with Bioactive Compounds through the Partial Replacement of Wheat Flour by Cocoa Bean Shells. Foods. 12(3):436.

Indexed at, Google Scholar, Cross Ref

Soumare, A., Soumare A, Diedhiou AG, Kane A (2022). Bambara groundnut: a neglected and underutilized climate-resilient crop with great potential to alleviate food insecurity in sub-Saharan Africa. J Crop Improv. 36(5): 747-767.

Indexed at, Google Scholar, Cross Ref

Talari A, & Shakappa D (2018). Role of pigeon pea (Cajanus cajan L.) in human nutrition and health: A review. Asian J Dairy and Food Res. 37(3): 212-220.